Bear Fail Safe System

Provides Backup Power and a Fail Safe controller that monitors your power system and RTU health

When they reach a certain level valves are opened to dump liquid into tanks or back into the pipeline. These control system and valve are pneumatically controlled meaning they are powered by pressurized gas. On the vast majority of wells this gas is actually the gas from the well itself. Industry calls this “fuel gas”, which is mostly made up of methane (a potent greenhouse gas). When the controls operate, this fuel gas is vented directly in the atmosphere.

One of the key issues with making a electric zero emission wellhead separator is safety. Fuel gas powered pneumatic valves have a spring return that move the valve to the safe position on loss of pressure. Most electric actuators do not have a backup power, and those that due are much more expensive.

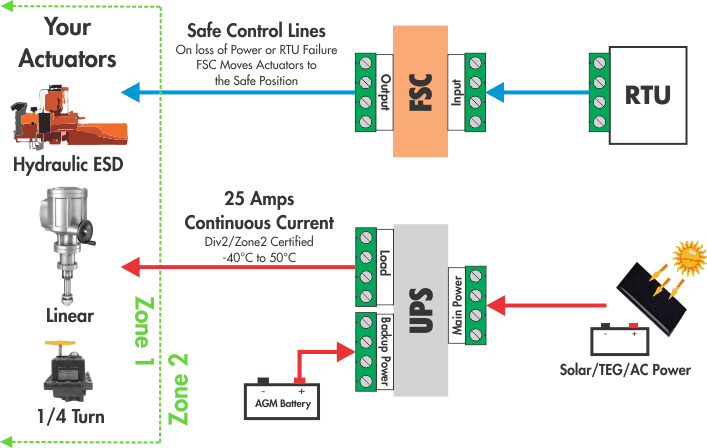

To solve this problem Calscan invented the Bear Fail Safe System. The heart of which is the Bear UPS and the patent pending Bear FSC (Fail Safe Controller) .

Simplified Bear System Overview

Simply put, the Bear UPS provides 25 Amps of continuous current when there is a power failure while the FSC monitors the health of the RTU, main and backup power source. When a failure has been detected the FSC will move up to nine DC electric actuators to the safe position automatically.

Visit the Bear Fail Safe product page for datasheets and a detailed reference design of how it all works