GHG Vent Gas Measurement

The Hawk Vent Gas Meter is designed to measure and digitally log extremely low flow vent gas, such as methane, with high accuracy. The Hawk is no lab grade toy. It is designed to be used unattended in the field where vent gas is not always clean and field conditions can be muddy.

Light weight, portable, hazardous location approved, designed and built in Canada for Canadian conditions. The Hawk is trusted by Industry, Governments and Academia across North America to provide accurate logged vent flow field data.

Low Flow Vent Gas Measurement

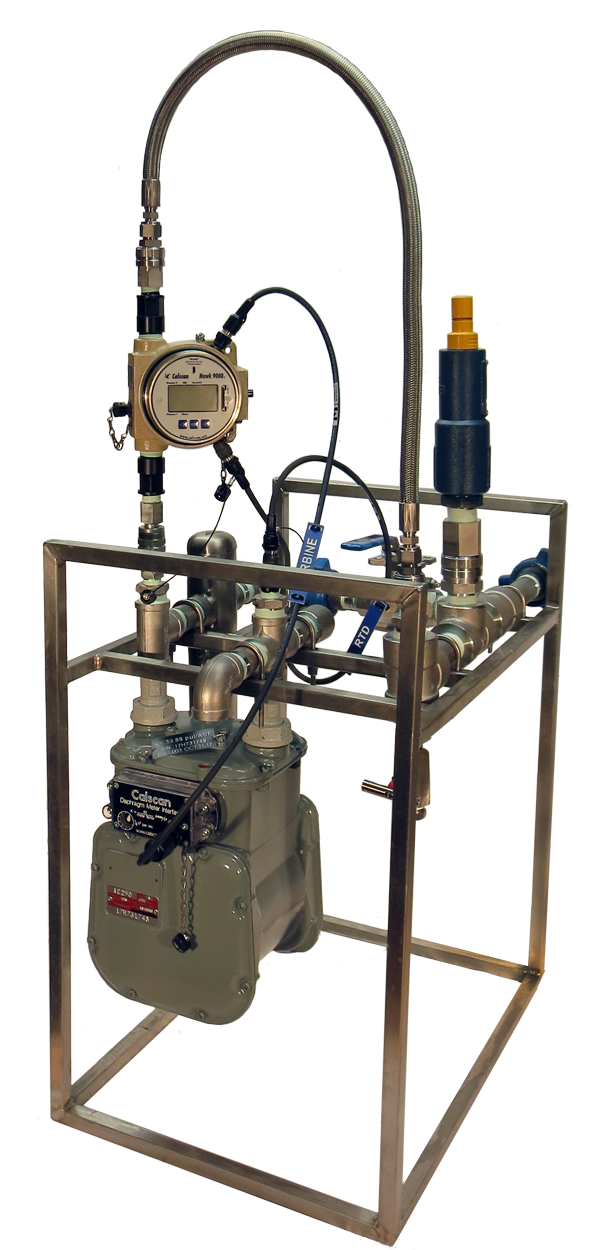

The Hawk configured with a positive displacement diaphragm meter can measure down to 1 cubic foot a day. Typically this is used for surface casing vent, compressor seals and pneumatic control gas usage

Low Back Pressure < 1 kPa

Wide Flow range: 0.028 m3/day to 340 m3/day (0.0012 m3/hr to 14.2 m3/hr )

Measurement accuracy <±2%

Light weight stainless steel frame and piping for low maintenance

Pressure and temperature compensated with industry standard flow equations

Logged data for ease of verification

Div 1 Class 1 Hazardous location approved

PDF report generation

Hawk Low Flow Vent Gas Measurement Brochure

Tank Vent Gas Measurement

OGI cameras are convenient but don't give a accurate gas rate. Direct measurement with a Hawk configured with a 2" gas turbine is a field proven tool for measuring tank vent gas with measurement accuracy <±3%. The turbine provides a wide turn down ratio and low backpressure help insure the thief hatches remained closed during your test, which is critical for accurate flow rates. As the Hawk does not require a accurate gas composition for measurement, it makes easy to get your flow rate no matter the gas mixture.

The light weight aluminum meter run has a built in sampling port to allow the operator to quickly get a gas sample if required

Please call for application assistance

Thermal Surface Casing Vent Integrity Service

The Hawk SGA ( Steam Gas Analyzer ) is designed to measure and log steam and other gas from SAGD well surface casing leaks. Using a high performance radiator and cooling tower the SGA will knock off the steam and weigh it to measure the mass flow rate. The remaining gas flow rate can then be measured and a sampled for further analysis.

knock off the steam and weigh it to measure the mass flow rate. The remaining gas flow rate can then be measured and a sampled for further analysis.

If H2S is detected a on board Cadmium Acetate bubble test can be preformed to determine if the H2S is biogenic or from a downhole formation which would indicated a well integrity issue..